Fairbanks Morse Engine Internship June-August 2018

Overview

I worked in the Research and Development department on projects directly related to the Trident Opposed Piston Engine. These projects consisted of conducting a failure analysis of an emissions testing probe before redesigning it, speeding up the startup of the engine, and creating a piston assembly cart to help technicians put in and take out pistons.

Design of the piston cart

Situation

In the 12 cylinder Trident opposed piston engine, the lower pistons are difficult to remove from the engine and the idea of a cart to assist the automotive technicians was proposed.

Task

I needed to design a SolidWorks model of a cart that would assist in putting in the lower engine pistons. The requirements needed were for the cart to be able to translated up and down in the vertical direction from 14 inches off of the ground all the way up to 34 inches to compensate for the possible engine stand configurations used by future customers. In addition to needing vertical mobility, the cart needs to have its angle adjustable to allow the technicians to install pistons in areas that are more complex due to piping getting in the way of the piston window.

Action

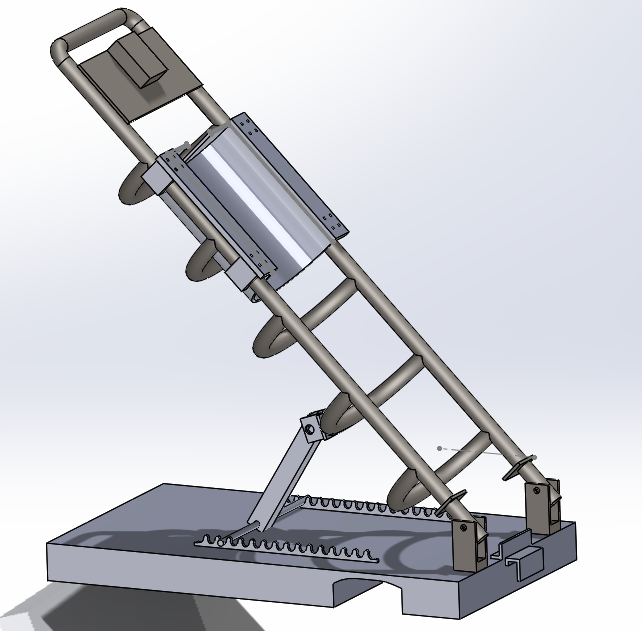

The cart model that meets these requirements is shown below. It is inspired by a regular hand truck. Therefore, a hydraulic cart that uses scissor bars to raise the table from 10” to 34” can be bought and modified to meet the requirements. The window to the lower pistons is about 14” off of the ground so the table needs to rise about 4” to align with the window. Another motivation for the vertical adjustment of the cart is also to be compatible with stands built by our customers. For example, the engine may be set up at a customer’s plant where the engine is sitting on the floor. Then the window would be around 34” above the ground. Therefore, the hydraulic cart is a way to adjust the height of the lower piston installation cart to fit each customers’ needs.

The hole is cut out on the bottom to get over the water pipe near some of the windows. This table depicted in the image above, will be stacked and fastened onto a standard hydraulic cart with the portion of the hole hanging off of the hydraulic table. The hydraulic cylinders on the table would interfere with creating the hole in the bottom of the cart’s platform itself. In addition, there is a L-shaped stop at the end of the rail system to catch the connecting rod if it happens to slide down the rails. The lip coming off of the table is used to hook into the piston window to guide the sled in. The end of the rails are pinned to allow the sleeve on the back to rotate the entire assembly. The sled itself will need to be lined with rubber to prevent scratching the outside of the piston skirt. At the top of the frame, there will be a winch (where the rectangular box is) that can hoist the piston on the sled up the rail system. The semi-circle bars will have to be removed except for the top and bottom bars acting as stops for the sled. The top handle will need to be removable in a fashion similar to telescoping metal tubes to initially slide the cart on and to replace the sled if needed in the future. The track on the platform will needed to be bolted down to allow angle adjustment.

Result

The Research and Development team at Fairbanks Morse Engine has a design to implement a cart that allows easier assembly of the Trident engine’s lower pistons. Therefore, FME can include this cart with the engine to establish better customer relations and have a competitive advantage. In addition, the company will save thousands over time with the increased efficiency of the lower piston assembly process.